PROCESS

Weaving is a labor-intensive process. I've simplified it into eight steps for those unfamiliar with it. Each stage of the process involves many considerations. The inspiration and weaving steps allow for more freedom and creativity while designing a pattern and dressing the loom, which requires meticulous planning and attention to detail. However, they all share a common thread: the human touch. When you purchase or receive a handwoven product, you are taking the essence of the maker and the time and care it took to produce the cloth.

ONE

Inspiration & Discovery

Inspiration is everywhere, and traveling is my favorite way to discover it. Everything I encounter—nature, architecture, culture, and experience—inspires my collections' mood, color, texture, and narrative.

TWO

Selecting Yarns

I like to hand-spin raw fibers into yarn and dye them with natural dyes for one-of-a-kind projects. For projects that require several yards, I purchase commercially spun yarns from small business suppliers in the U.S. and Canada. When choosing yarns, I consider the fabric's intended end use and then decide what fibers to use, sometimes blending, to achieve my desired results.

THREE

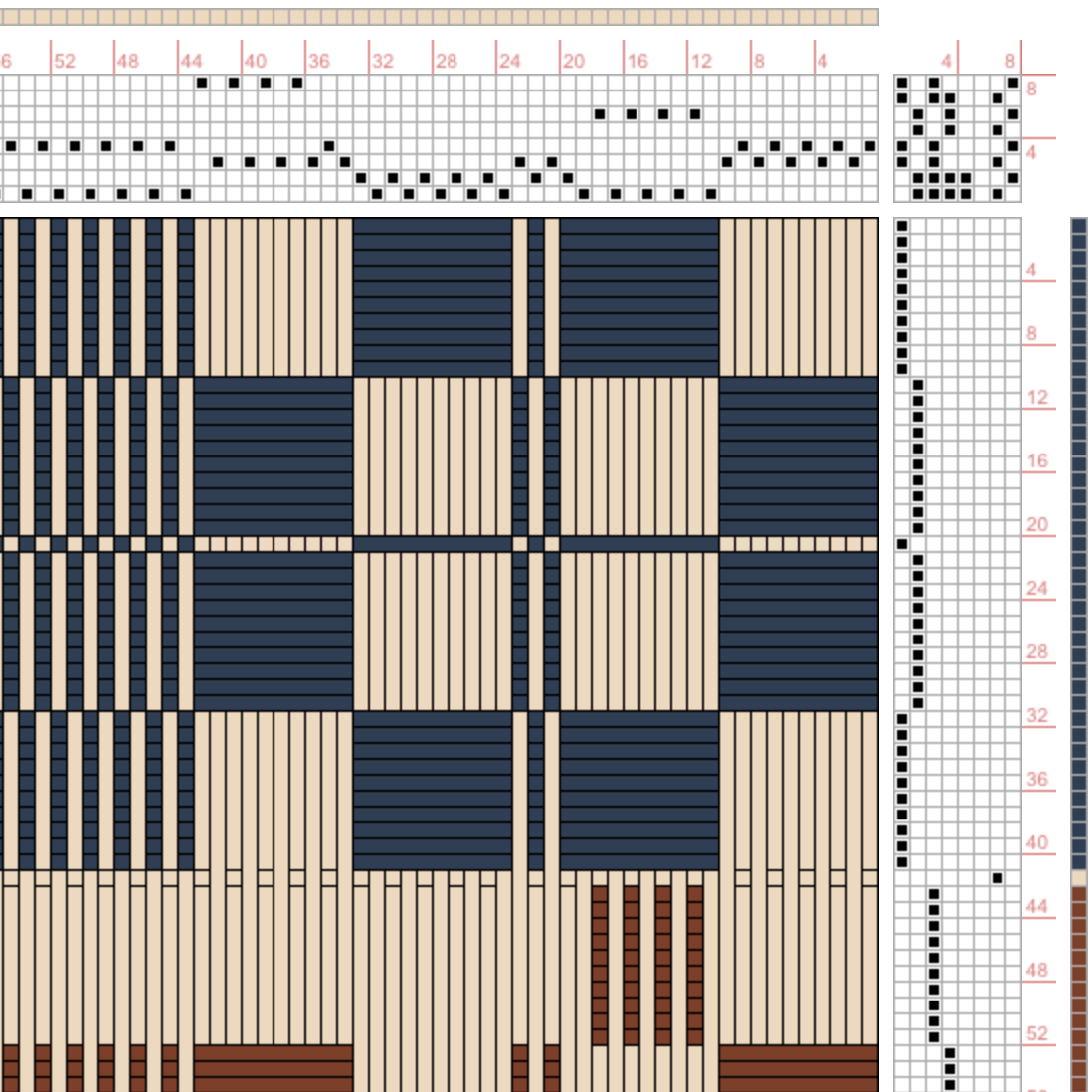

Designing a Pattern

I create my patterns using weaving software. This part of the process takes only a little time, but I can quickly generate ideas, allowing me to experiment with color and weave structures. It is at the loom that the patterns come to life and reveal surprises.

FOUR

Creating the Warp

This Leclerc stand-up warping mill is the same type that I used in college and what I use to make all of my warps. It is ideal for making long warps and allows good ergonomics. I bought it from a former professor at MCAD who no longer needed to make long warps. She had owned it for 55 years before I acquired it.

FIVE

Dressing the Loom

Before I start weaving, I dress my loom. Each meticulous step is important. I place the warp evenly on the back beam, roll the warp onto the back beam, and apply even tension throughout the width. Next, I thread the yarns through the heddles and through the reed. Finally, I tie the warp yarns to the front rod.

SIX

Winding Bobbins

All of my weft yarns are wound using a Schact double-ended bobbin winder. I wind several at a time. These bobbins are placed onto a boat shuttle, and it is that tool that you pass back and forth horizontally to weave the fabric.

SEVEN

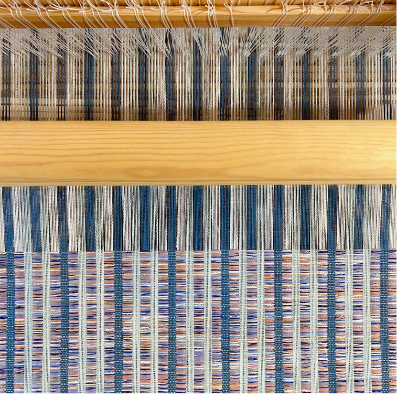

Weaving the Fabric

I have two looms in rotation, allowing me to weave various fabric structures, such as plain, twill, satin double cloth, and monk's belt. The Oxaback Lilla is an eight-harness Swedish countermarch loom, and the Schacht Baby Wolf is a four-harness jack loom. The Oxaback has a 39" weaving width, and the Schacht has a 24" weaving width.

EIGHT

Finishing & Sewing

After I remove the fabrics from the loom, I finish them with care. I wet-finish the pieces with water and mild soap. This practice shrinks the textiles and allows the fibers to bloom. The cloth is then ready to be cut and sewn.